Supply chain and channel management snack attack – In the realm of consumer goods, the ‘snack attack’ phenomenon presents unique challenges and opportunities for supply chain and channel management. This article delves into the intricacies of managing these aspects in the face of sudden and unpredictable demand surges, exploring strategies for optimization and resilience.

As we navigate the complexities of snack attack management, we will examine the impact on supply chain efficiency, identify effective distribution channels, design robust inventory systems, and highlight the significance of collaboration and innovation.

1. Supply Chain and Channel Management in the Snack Attack Industry

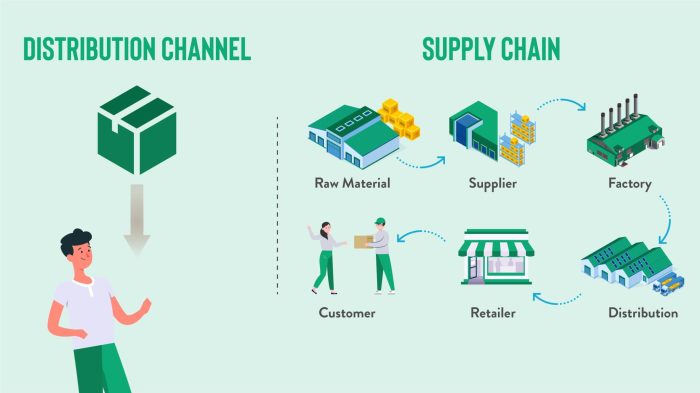

The snack attack industry presents unique challenges and opportunities in managing supply chains and channels. Sudden and unexpected demand surges require agile and resilient supply chains, while effective channel selection and management are crucial for reaching consumers.

Successful strategies include:

- Establishing partnerships with suppliers to ensure reliable product availability.

- Utilizing advanced inventory management systems to optimize stock levels and minimize waste.

- Investing in distribution channels that can handle rapid order fulfillment.

Unsuccessful strategies often involve:

- Overreliance on a single supplier, leading to supply disruptions.

- Inefficient inventory management, resulting in stockouts or excess inventory.

- Poor channel selection, limiting market reach and sales potential.

2. Impact of Snack Attacks on Supply Chain Efficiency: Supply Chain And Channel Management Snack Attack

Sudden demand surges during snack attacks can significantly impact supply chain efficiency. Operations may experience:

- Increased order volume and order fulfillment challenges.

- Disruptions in production and distribution due to overwhelmed systems.

- Delays in product delivery, leading to customer dissatisfaction.

To mitigate risks and improve resilience, companies can:

- Implement flexible production schedules to accommodate fluctuating demand.

- Build strategic partnerships with multiple suppliers to ensure supply continuity.

- Invest in technology to automate processes and enhance supply chain visibility.

3. Channel Optimization for Snack Attack Distribution

Effective distribution channels are essential for reaching consumers during snack attacks. The most effective channels include:

- Convenience stores and gas stations, due to their widespread availability and extended hours.

- Online retailers, offering a wide selection and home delivery options.

- Vending machines, providing convenient access in high-traffic areas.

Channel selection and management strategies should focus on:

- Analyzing consumer behavior and preferences to identify target markets.

- Negotiating favorable distribution terms and agreements.

- Monitoring channel performance and adjusting strategies as needed.

4. Inventory Management for Snack Attack Preparedness

Managing inventory effectively is crucial to meet the volatile demand of snack attacks. A robust inventory management system should:

- Utilize forecasting techniques to predict future demand.

- Establish safety stock levels to buffer against unexpected surges.

- Implement automated replenishment systems to maintain optimal stock levels.

| Best Practices for Inventory Forecasting and Replenishment |

|---|

| Use historical data and market trends to predict demand. |

| Monitor real-time sales data to adjust forecasts. |

| Establish clear reorder points and safety stock levels. |

| Automate replenishment processes to minimize human error. |

5. Collaboration and Coordination in Snack Attack Management

Collaboration between suppliers, distributors, and retailers is essential for managing snack attacks effectively. Successful collaborations involve:

- Establishing clear communication channels to share demand forecasts and inventory levels.

- Coordinating production and distribution schedules to meet peak demand.

- Sharing best practices and lessons learned to improve overall efficiency.

Case studies of successful collaborations include:

- The partnership between PepsiCo and Walmart, which leverages data analytics to optimize inventory levels and meet consumer demand.

- The collaboration between Mondelez and Amazon, which provides a wide selection of snack products through Amazon’s Prime Now service.

Query Resolution

What are the key challenges in managing supply chains for snack attacks?

Sudden and unpredictable demand surges, perishable inventory, and the need for agile distribution networks.

How can companies optimize their distribution channels for snack attacks?

Identify the most effective channels, establish strategic partnerships, and leverage technology for real-time inventory visibility.

What inventory management strategies are effective for snack attack preparedness?

Implement safety stock buffers, utilize demand forecasting tools, and optimize replenishment cycles.